A Comprehensive Guide to Water Ballast Management System in 2025

The International Maritime Organization (IMO) has introduced fundamental changes to the way vessels document ballast water operations. These amendments, which entered into force on 1 February 2025, are not merely a bureaucratic update but a direct response to identified, industry-wide compliance issues that undermined the effectiveness of the International Convention for the Control and Management of Ships’ Ballast Water and Sediments (BWM Convention).

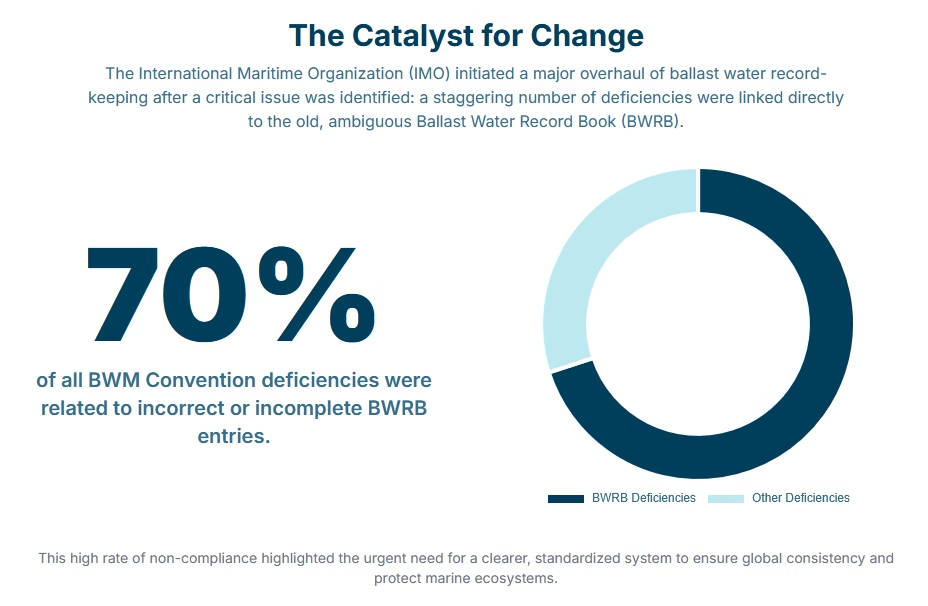

The primary impetus for this reform was the alarming rate of deficiencies found during Port State Control (PSC) inspections. Analyses revealed that incorrect or incomplete entries in the Ballast Water Record Book (BWRB) accounted for over 70% of all deficiencies related to the BWM Convention. This statistic clearly indicated that the previous format of the Record Book, due to its ambiguity, created significant interpretational problems for both crews and inspectors.

This issue was also raised by industry organizations themselves. INTERTANKO actively sought clarification from the IMO, pointing to “conflicting interpretations” regarding proper record-keeping from various Flag Administrations, classification societies, and PSC authorities. This industry pressure underscored the urgent need for a clearer, standardized legal framework that would eliminate room for arbitrary interpretation.

The IMO’s response was decisive action during the 80th session of the Marine Environment Protection Committee (MEPC 80) in July 2023. The key outcome of the session was the adoption of Resolution MEPC.369(80) on 7 July 2023, which thoroughly revises the BWRB format contained in Appendix II of the BWM Convention. The new, highly structured format, modeled on the proven Oil Record Book from the MARPOL Convention, was designed to eliminate previous ambiguities.

The introduction of such precise recording standards marked the end of an era where “ambiguity of regulations” could serve as a line of defense when a deficiency was cited. The previous system, full of general phrasing, created a “grey area” where a crew could make entries in good faith yet still be held accountable by a PSC inspector with a different interpretation. The new system, with its specific letter codes (A-H) and numbered items, has minimized the freedom of interpretation. Consequently, the burden of proof during an inspection has shifted to the vessel, which must now demonstrate strict adherence to a clear, detailed checklist. This means that PSC authorities are likely to show less leniency for errors, as the rules have become significantly more explicit.

The IMO’s actions also signify a strategic shift in approach—from reactively patching legal loopholes to proactive, comprehensive reform. The persistently high number of record-keeping deficiencies proved that minor adjustments and circulars were insufficient. The decision to completely overhaul Appendix II through Resolution MEPC.369(80) and to develop detailed operational guidelines in circular BWM.2/Circ.80 demonstrates that the IMO identified and resolved to fix fundamental flaws in the system. This has established an important precedent for future revisions of other documentation requirements in shipping.

New BWRB Format under MEPC.369(80)

Resolution MEPC.369(80) introduced a revolutionary change to the structure of the Ballast Water Record Book, transforming it from a descriptive document into a precise, codified register of operations. This transformation was intended to ensure transparency, standardization, and to facilitate the verification of compliance.

Structural Comparison and New Entry Categories

The fundamental change was the move away from loosely defined entries to a highly organized system of letter codes (from A to H) and their assigned numbered items. Such a structure is well-known to crews from other mandatory ship’s logbooks, which has accelerated adaptation to the new requirements.

The most significant innovation was the introduction of dedicated codes for operations that were previously documented in a non-uniform manner or were not codified at all. Two new codes are of key importance for transparency and full traceability of actions:

- Code (F) Failures and inoperabilities of the ballast water management system (BWMS): Requires a precise record of any malfunctions, shutdowns, or critical alarms that could indicate non-compliance with the D-2 standard. This was a fundamental change towards operational transparency.

- Code (G) Ballast tank cleaning/flushing, removal and disposal of sediments: For the first time, this formalized the duty to document sediment management, a key vector for the transfer of invasive species. This includes both the removal of sediments to port reception facilities and their disposal into the marine environment in accordance with the Ballast Water Management Plan (BWMP).

Even standard operations, such as the uptake (Code A) and discharge (Code B) of ballast water, now require significantly more detailed information. For each of these operations, it is mandatory to indicate the “Ballast water treatment method” used during the specific operation and to precisely identify all “tanks affected by the operation”.

The following tables present the key changes and the new structure of the Record Book.

Table 1: Comparison of Ballast Water Record Book Format – Old vs. New (MEPC.369(80))

| Previous Entry Format | New Entry Format – MEPC.369(80) |

| When ballast water is taken on board | Code A – When ballast water is taken on board from the aquatic environment (ballasting operation) |

| When ballast water is discharged into the sea | Code B – When ballast water is discharged into the aquatic environment (deballasting operation) |

| Whenever ballast water is exchanged | Code C.1 – Ballast water exchange |

| Accidental or other exceptional uptake or discharge | Code E – Accidental discharge/ingress or other exceptional uptake/discharge |

| (No dedicated code) | Code F – Failures and inoperabilities of the ballast water management system |

| (No dedicated code) | Code G – Ballast tank cleaning/flushing, removal and disposal of sediments |

| Additional operational procedures and general remarks | Code H – Additional operational procedures and general remarks |

Table 2: Comprehensive Guide to New Codes and Required Entries in the BWRB (in accordance with Resolution MEPC.369(80))

| Code | Operation Description | Required Items for Entry (by number) |

| A | Uptake of ballast water from the aquatic environment (ballasting) | .1 Start time and location;.2 Completion time and location;.3 Identity of tank(s);.4 Estimated volume of uptake and final total quantity retained;.5 Whether conducted in accordance with BWMP;.6 Ballast water treatment method. |

| B | Discharge of ballast water into the aquatic environment (deballasting) | .1 Start time and location;.2 Completion time and location;.3 Identity of tank(s);.4 Estimated volume of discharge and final total quantity retained;.5 Whether conducted in accordance with BWMP;.6 Ballast water treatment method. |

| C | Ballast water exchange, treatment through internal circulation or in-tank treatment | C.1 Ballast water exchange:.1 Start time and location;.2 Completion time and location;.3 Min. distance from land and min. depth;.4 Whether in accordance with BWMP and exchange method;.5 Identity of tank(s);.6 Total quantity exchanged and final total quantity retained;.7 Ballast water treatment method. C.2 Internal circulation or in-tank treatment:.1 Start time and location;.2 Completion time and location;.3 Identity of tank(s);.4 Total quantity treated;.5 Ballast water treatment method. |

| D | Uptake/discharge of ballast water from/to a port-based or reception facility | .1 Start time and location;.2 Completion time;.3 Type of operation (uptake/discharge);.4 Identity of tank(s);.5 Total quantity and final total quantity retained;.6 Whether in accordance with BWMP;.7 Onboard ballast water treatment method. |

| E | Accidental discharge/ingress or other exceptional uptake/discharge | .1 Start time and location;.2 Completion time;.3 Type of operation;.4 Identity of tank(s);.5 Total quantity of ballast water;.6 Circumstances, reason, treatment method used, and general remarks. |

| F | Failures and inoperabilities of the ballast water management system (BWMS) | .1 Time and location of failure/inoperability;.2 Operation being performed at the time;.3 Description of failure/inoperability;.4 Time and location of restoration of BWMS to operational status. |

| G | Ballast tank cleaning/flushing, removal and disposal of sediments | .1 Start time and location;.2 Completion time and location;.3 Identity of tank(s);.4 Discharge/disposal to reception facility (quantity, name);.5 Discharge/disposal to aquatic environment (quantity, min. distance from land, min. depth). |

| H | Additional operational procedures and general remarks | Entries concerning, inter alia, internal transfers of ballast water, sampling, taking a tank out of service, reporting failures to the administration, etc. |

The new, structured format is more than just a convenience for paper records; it forms the foundation for effective digitalization. The previous format, with its descriptive sections, was difficult to digitize efficiently. The new structure of codes and items, however, creates discrete, machine-readable data fields (e.g., Code_F_Item_3_Description_of_Failure). This allows software developers (such as NAPA) to create advanced applications with drop-down lists, automatic data validation, and easy integration with other shipboard systems. In this way, the new paper format becomes a data standard that paves the way for the mandatory approval of electronic Ballast Water Record Books (e-BWRBs) and opens up possibilities for future automation of reporting.

Operational Guidelines in Practice: Applying BWM.2/Circ.80/Rev.1

Knowledge of the new BWRB format alone is insufficient; understanding how to apply it correctly in daily operational practice is crucial. IMO Circular BWM.2/Circ.80/Rev.1 serves as a detailed manual for crews, translating regulatory requirements into specific, scenario-based instructions.

General Principles for Making Entries

Before addressing specific operations, the circular establishes fundamental principles for maintaining the Record Book to ensure consistency and legibility:

- Date and Time Format: The format dd-MMM-yyyy (e.g., 01-JUN-2022) must be used. Time should be recorded in UTC and SMT (Ship’s Mean Time).

- Location: Port names should be entered using standardized UN/LOCODEs. In their absence, or for offshore terminals and anchorages, the full name of the port and country must be entered.

- Quantities: All volumes of ballast water must be estimated and recorded in cubic metres (). It is noteworthy that the entry “final total quantity retained” refers to the total quantity of ballast water on the entire ship, not in individual tanks, as clarified by administrations such as Liberia.

- Language: Entries must be made in the working language of the ship. If this is not English, French, or Spanish, the entries must include a translation into one of these languages.

- Corrections and Signatures: Each entry must be signed by the officer in charge of the operation, and each completed page by the master. Incorrect entries must be struck through with a single line, remaining legible, signed and dated, and then the correct entry must be made.

Guide to Standard and Advanced Operations

Circular BWM.2/Circ.80/Rev.1 provides detailed examples for each category of operation:

- Standard Operations (Codes A, B, C.1): These pertain to routine uptake, discharge, and exchange of ballast water. Correctly identifying the treatment method is key. For example, a ship complying with the D-1 standard (exchange) will enter “None” upon uptake. A ship with the D-2 standard (treatment) will enter “Approved BWMS”. For systems that treat in-tank or during the voyage, rather than on uptake, “None, as per BWMS design” should be entered.

- Advanced and Non-Standard Operations (Codes C.2, D, E, G, H): The circular precisely describes how to document more complex scenarios, such as water treatment via internal circulation (Code C.2), discharge to a port reception facility (Code D), accidental flooding of a tank (Code E), sediment removal (Code G), or internal transfers of water between tanks for stability purposes (Code H).

Special Attention: Recording BWMS Failures (Code F) and Operations in Challenging Water Quality (CWQ)

Two operational situations have been given special status in the new guidelines due to their high risk and frequent interpretation problems.

1. Failures and Inoperabilities (Code F): The guidelines distinguish between a “failure” (e.g., a critical alarm, system shutdown) and an “inoperability” (e.g., filter clogging in turbid water, which does not necessarily mean the system is broken). In both cases, an entry must be made under Code F, describing the problem. Importantly, if the issue is not resolved immediately, a second entry under Code F must be made after the problem is fixed and the system is restored to full operational status, thereby closing the event.

2. Challenging Water Quality (CWQ): This is one of the most significant additions in the circular, formalizing procedures for situations where water quality prevents the BWMS from operating correctly. The guidelines introduce two key scenarios:

* Reactive Bypass: Occurs when the BWMS fails or becomes inoperable unexpectedly due to CWQ (e.g., sudden filter clogging). The crew must document this event under Code F and then take action according to the contingency plan.

* Pre-emptive Bypass: Permissible when, based on information about conditions in the loading port, it can be anticipated that the BWMS will be unable to operate correctly. Such an operation, however, requires prior communication with and consent from the Flag Administration and/or the port State.

These new guidelines created a kind of “safe harbour” for documented operational non-compliance. Previously, bypassing a BWMS was seen as a clear violation. Now, thanks to formal recording procedures for failures and CWQ scenarios, the focus has shifted from the act of bypassing the system to the quality of the documentation.

For a PSC inspector, an undocumented bypass remains a serious deficiency. However, a bypass that is properly recorded using the correct codes, with detailed remarks and evidence of communication with authorities, becomes proof that the crew acted in accordance with the approved contingency plan. This, in turn, elevates the importance of the contingency sections in the BWMP, which must now contain precise procedures for BWMS failures and operations in CWQ conditions.

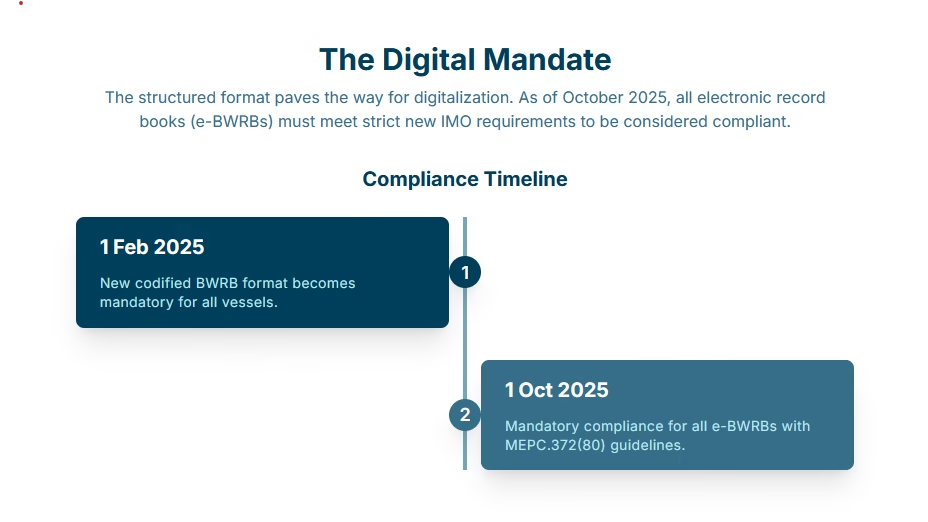

Compliance for Electronic Record Books (e-BWRBs)

In parallel with the reform of the paper Record Book format, the IMO is introducing a rigorous and mandatory legal framework for its electronic counterparts. Although e-BWRBs were permitted previously, their use largely occurred in a regulatory vacuum. This state of affairs will end on 1 October 2025, when new, obligatory requirements will come into force.

New Regulatory Framework for e-BWRBs

The legal basis for this digital transformation is provided by two key IMO documents:

- Resolution MEPC.372(80): Establishes the “Guidelines for the use of electronic record books under the BWM Convention.” It specifies detailed technical and functional standards that e-BWRB software must meet, including data integrity, protection against tampering, and audit capabilities.

- Resolution MEPC.383(81): Introduces amendments to Regulations A-1 and B-2 of the BWM Convention, which give the guidelines from MEPC.372(80) mandatory status. From 1 October 2025, every e-BWRB used on a ship must comply with these guidelines.

The Two Pillars of e-BWRB Compliance

For a ship to legally use an electronic Record Book after 1 October 2025, two fundamental conditions must be met:

- System Approval: The e-BWRB software itself must have formal approval (e.g., type approval) issued by the Flag Administration or a Recognized Organization (RO) authorized by it (e.g., DNV, LR, ABS). Software manufacturers must submit their systems for rigorous verification to obtain such a certificate.

- Ship-specific Declaration: The ship must carry on board an individual “Declaration,” issued by the Flag Administration or RO, which confirms that the specific installation of the approved system on that vessel complies with the requirements. The absence of this declaration during a PSC inspection could result in the rejection of all electronic records as non-compliant with the Convention.

This process creates a new market for compliance technology and a new, unavoidable administrative task for shipowners. Previously, any software provider could offer an “electronic logbook” without formal oversight. The new regulations introduce a high barrier to entry, favouring established providers capable of investing in the certification process. For shipowners, this is no longer just a software purchase but a formal certification process involving cooperation with the flag/class, installation reviews, and obtaining new documentation. This generates additional costs and administrative complexity, which is a significant side effect of the digital transformation.

It should also be emphasized that the transition to an electronic format does not change the data retention periods. Records must be available on the ship for at least two years from the last entry and then kept under the company’s control for another three years.

Recommendations for Shipowners, Managers, and Crews

The effective implementation of such wide-ranging changes required an integrated and proactive approach. The following recommendations serve as a strategic guide that was intended to ensure a smooth transition and long-term compliance with the new requirements.

1. Crew Training and Familiarization

This was the most critical and urgent step. The success of the implementation depended on the competence of the officers responsible for maintaining the Record Book. Training had to cover:

- Thorough familiarization with the new code structure (A-H) and the detailed items required for each operation.

- Practical exercises on recording procedures for new, critical scenarios: BWMS failures and inoperabilities (Code F) and operations in CWQ conditions.

- Understanding the principles of making entries in accordance with the guidelines in BWM.2/Circ.80/Rev.1.

2. Replacement and Management of the Ballast Water Record Book

Before the 1 February 2025 deadline, specific logistical actions had to be taken:

- Procurement: New paper versions of the BWRB had to be ordered and delivered to ships (available from publishers like Witherbys or directly from some administrations, e.g., BMA), or electronic systems had to be updated to the latest compliant version.

- Transition: The guidelines of the Flag Administration had to be followed. A good practice, recommended by the Bahamas for example, was to formally close the old Record Book (by striking through unused pages) and start a new one. When using up old stock, it was crucial to attach a printout of the new introductory pages and instructions from MEPC.369(80).

- Early Implementation: Administrations such as Liberia and the Bahamas encouraged the voluntary, early adoption of the new format, which could help crews become accustomed to the changes before the final deadline.

3. Review of the Ballast Water Management Plan (BWMP)

Although the change in the BWRB format itself generally did not require re-approval of the entire BWMP by class, it was strongly recommended to conduct an internal review of the plan to:

- Update References: In accordance with amendments to the G4 guidelines (Resolution MEPC.370(80)), the BWMP section on record-keeping should now refer to the new Record Book format and the guidelines contained in circular BWM.2/Circ.80/Rev.1.

- Strengthen Contingency Plans: Contingency procedures for BWMS failures and operations in CWQ conditions had to be verified and, if necessary, expanded to be fully consistent with the new, formalized documentation requirements.

4. Preparation for Port State Control Inspections

PSC inspectors now have a much more precise tool for verification. Inspections focus on:

- The correct application of the new format and codes A-H.

- The completeness and detail of entries for all operations.

- The proper documentation of any BWMS failures (Code F) and sediment-related operations (Code G).

- Consistency between the entries in the BWRB, the procedures in the BWMP, and the actual state of ballast water in the tanks.

- For ships with e-BWRBs (after 1 October 2025), the presence and validity of the ship-specific Declaration.

5. Implementing Best Practices: The Value of a Voluntary Tank-by-Tank Log

Circular BWM.2/Circ.80/Rev.1 promotes the keeping of a voluntary, detailed log of operations for each tank separately (tank-by-tank log). Although not mandatory, this practice offers strategic benefits:

- Facilitates Reporting: It significantly simplifies the completion of Ballast Water Reporting Forms (BWRFs), which are required by some port States.

- Increases Transparency: It provides a granular audit trail that allows for quick and precise demonstration of compliance and explanation of each tank’s contents to an inspector, which can shorten inspection times.

- Supports the Crew: It helps the crew to effectively implement the BWMP through better, real-time awareness of the ship’s ballast condition.

In summary, ensuring compliance with the new regulations is a dual-track process. Onshore management must oversee two parallel but interconnected streams of activity. The first is the procedural and substantive stream, covering crew training and the implementation of new operational procedures. The second is the technological and certification stream, related to the procurement, installation, and formal approval of e-BWRB systems. Failure in either of these areas results in overall non-compliance. A ship may have a perfectly approved e-BWRB system, but if the crew makes incorrect entries, it will be a deficiency. Conversely, perfectly kept records in an unapproved electronic system will also constitute a deficiency after 1 October 2025. This is a new, more complex management challenge, requiring attention both on board and in the shipowner’s office.